Die casting allows manufacturers to produce metal parts with complex shapes using dies that are made from reusable moldings. The applications of die casting are far reaching and vary from the automotive to aerospace industry. Projects that involve high volume production are most suited for this process because the simplicity and low maintenance of the tools make it possible to create parts in bulk without taking too much time. Procedures differ, and your specific requirements will dictate the most suitable die casting technique to choose. The wrong process can ruin your whole project, which is a huge waste of raw material and other resources. Although the basics are the same- inject molten metal into a mould; some variables distinguish one procedure from the next.

Aluminum Die Casting

The material is one of the aspects that differentiate casting processes. Products manufactured from aluminum die casting have specific properties that make them preferable in a myriad of applications. The low density and lightweight nature of the metal not only makes it easy to cast but also cater to industries where weight is of great importance such as in computing and networking infrastructure. Die castings of aluminum have superior durability, which adds to their excellent electrical conductivity. The finishing on aluminum die casting is perfect, which is a huge factor when manufacturing products for decorative purposes. Aluminum’s high resistance to corrosion is another trait that makes it a viable solution for many metal parts.

Pressure Die Casting

Vacuum pressure casting is an economical solution in the manufacture of detailed metal components and is very effective in removing bubbles from products. Air and gas can get trapped inside metal parts when being forced into a die, causing porosity, which can lead to rejection of the products. In the process, the mould is placed above the molten metal bath while the cylinder chamber forms a vacuum that forces she liquefied metal into the cavity. However, the creation of a vacuum depends on the particular die casting method in use. With pressure die casting, the amount of gas that is included in the process is limited and so is the turbulence. This die casting technique is ideal when doing heat treatment in post-casting.

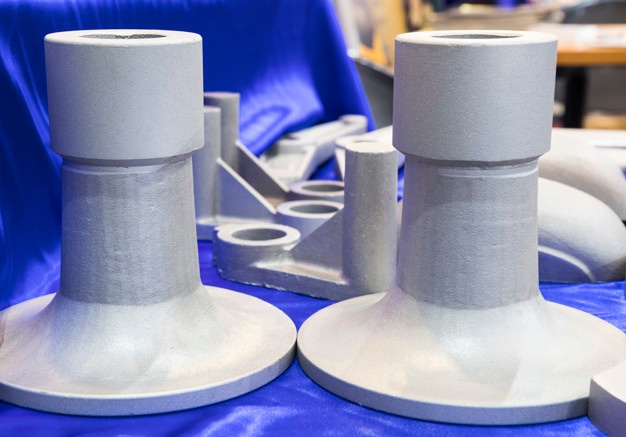

Gravity Die Casting

The method is primarily utilized on non-ferrous alloy components such as zinc, aluminum and copper. Instead of relying on pressure to force the molten metal into the die cavities, this technique takes advantage of gravity. The liquefied metal is allowed to enter the die from the lower part, consequently creating a “down sprue”, which reduces turbulence and prevents porosity. Products manufactured using gravity die casting have excellent dimensional accuracy, in addition to very smooth surfaces. Compared to sand casting, the process makes it possible to get very thin walls on metal parts.

Structural Die casting

Structural applications require die casting processes that are more sophisticated. The process is a major contributor to the automotive industry and provides numerous aluminum components from doors to brackets. Aluminum is utilized in structural diecasting when there is a need to replace heavy parts with lightweight materials such as in the suspension system. In applications that require thick-walled surfaces, structural die casting of aluminum is the perfect solution. The process also results in products of superior performance, not to mention the precise designs allow automation without problems.

For more information about Die casting malaysia, please visit https://stx.com.my/